Extreme weather, humid and salty air, confined spaces, restricted access and, last but not least, classification of hazardous areas—these all affect the daily work on an oil rig. This makes it the ideal location to carry out a field test of the latest generation of intrinsically safe mobile devices—a combination of the Visor-Ex 01 smart glasses and the tried-and-tested Smart-Ex® 02 smartphone. Any product that withstands these harsh conditions can also be used in all other process industries, such as the chemical, petrochemical, and pharmaceutical industries.

Carl Henderson, Global Account Manager—Mobility at Pepperl+Fuchs in the UK, knows what he is talking about. He has been monitoring the various field tests of the Visor-Ex 01 from the beginning. Even in the pilot phase, Pepperl+Fuchs ecom relied on the involvement and practical experience of its customers.

Smart Service and Maintenance: The Call for Greater Efficiency and Sustainability

Far out at sea, conditions are extremely adverse, and plant servicing and technical support sometimes require a high level of expertise, so a significant number of employees have to travel around the world to share their knowledge. Therefore, modern and efficient communication technologies are more in demand than ever. "The oil and gas industry is keen to increase wrench time, while environmental issues and sustainability are more and more at the forefront," says Henderson. “The idea of subject matter experts flying around the world to asses a situation is expensive, inefficient and also leads to an excessive carbon footprint, making digital solutions to connect workers extremely attractive.” Oil and gas companies are looking for efficient and sustainable digital solutions to reduce emissions, costs, and inefficient use of resources, without any compromise on safety. This is where IIoT solutions come in. “We needed to create a solution that allows remote experts and field workers to connect and collaborate in an instant, built upon a highly reliable, ultra-rugged platform. At the same time, a wide range of connectivity options was a necessity; with many rigs moving away from Wi-Fi and relying instead on private mobile networks, it was important to have all bases covered,” Henderson explains.

The idea of subject matter experts flying around the world to asses a situation is expensive, inefficient and also leads to an excessive carbon footprint, making digital solutions to connect workers extremely attractive.

Remote Experts: Digital Support from Afar

Remote support solutions are becoming more and more attractive, especially in the field of servicing and maintenance, since the number of oil rig personnel should be kept to a minimum for reasons of safety, cost, and time. "With up to 10,000 maintenance activities per month on an offshore platform, leaner processes are therefore a significant efficiency factor," Henderson points out. "As a result, oil and gas companies are increasingly looking for suitable digital solutions that also meet the high degree of protection needed in hazardous zones and divisions," he adds. There is a great potential for efficiency here, waiting to be tapped.

The pandemic has significantly accelerated this development and the need for industrial grade and intrinsically safe smart glasses and wearables. "For a long time, restrictions on contact and travel prevented mobile workers on the oil rig from receiving in-person help from remote experts on the mainland," recalls Jörg Hartleb, Head of Product Management at Pepperl+Fuchs ecom. "This made it even more urgent for companies to optimally support their teams from a distance." At the end of 2020, Pepperl+Fuchs ecom therefore entered crunch mode in the development of the Visor-Ex 01, and the first samples for extensive field and application tests were sent to selected customers as early as June 2021.

With the Visor-Ex 01, we have truly succeeded in setting new standards in the field of industrial-strength and intrinsically safe smart glasses.

Unique Smart Glasses for Hazardous Areas

"We faced enormous challenges in the development of the Visor-Ex 01," says Hartleb. "We had to actualize extremely sophisticated technology with a rugged but also complex design. All this without losing sight of our ambitious goal of developing a lightweight device that is comfortable to wear and meets all requirements of explosion protection. With the Visor-Ex 01, we have truly succeeded in setting new standards in the field of industrial-strength and intrinsically safe smart glasses," says Hartleb. "This is especially true in terms of usability, lightweight design, flexibility, and safety—all qualities that are extremely important to our customers," Henderson adds.

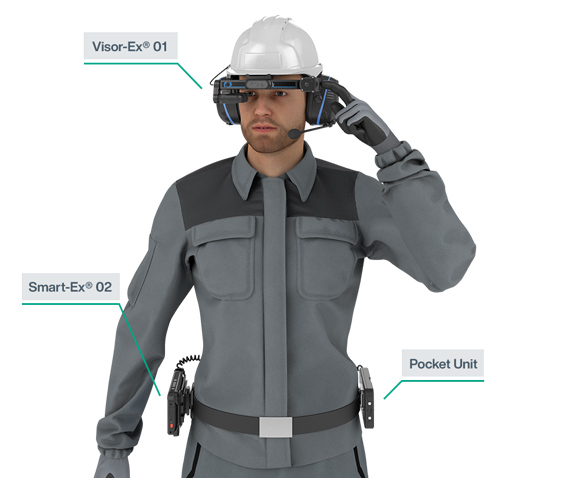

And indeed, the Visor-Ex 01 smart glasses, weighing 180 grams, are less than half the weight of comparable products on the market. This is made possible by the advanced system solution consisting of the Visor-Ex 01, the Smart-Ex 02 smartphone, and an external pocket unit used as a CPU unit, which can be easily attached to a belt. This keeps the weight on the head as low as possible. Naturally, the smart glasses can also be attached to any protective helmet.

Through the Eyes of the Mobile Worker

The Visor-Ex 01 has three cameras, two of which are 16 MP cameras that are centrally positioned and can be individually controlled. "This means that the remote expert can see exactly the same view as the mobile worker on-site at the plant," explains Hartleb. The third camera on the side has a 6x optical zoom and enables the reading of barcodes on plant components, for example. The user views the corresponding information directly on the OLED display. The display can be placed in front of the user's dominant eye, whether left or right. It is extremely slim and can be optimally positioned so that it barely limits the field of view and the information appears to float against the background. If the Visor-Ex 01 display is not currently required, it can be easily folded out of the field of view, providing a clear view of the plant.

Four built-in microphones and a speaker enable interference-free voice contact between the mobile worker and remote expert. For especially noisy environments, a headset can be connected to the Visor-Ex 01 via Bluetooth or a 3.5 mm jack plug. "With smart glasses, mobile workers have both hands free to work and hold on safely. This is another safety factor, not only in some plants, but also when climbing ladders or scaffolding on an oil rig," Henderson points out.

Digital Workflows and IIoT Application Scenarios

The intrinsically safe smart glasses open up a wide range of possible IIoT application scenarios. In addition to remote support, other applications of the Visor-Ex 01 include connection to an asset management system for quick and simple access to data directly on-site, for example during regular inspections. The Visor-Ex 01 was also able to demonstrate its strengths in this field during the practical test. Due to the combination of high-resolution cameras and integrated image processing, QR codes on devices and machines can be scanned in order to directly access the required information, such as datasheets or installation notes, via the associated Smart-Ex 02 smartphone.

The Visor-Ex solution scored especially highly in the documentation of faults. "Mobile workers are able not only to record the causes of the fault digitally, but also to supplement the information with photos or video recordings," explains Henderson, adding: "The digitized information can therefore be shared in real time with remote support experts around the world—whether within the company or externally with an OEM (Original Equipment Manufacturer) using the intrinsically safe smartphone." The smart glasses do not establish the connection directly via radio, but via the associated Smart-Ex 02 smartphone. The Smart-Ex 02 uses a robust LTE connection to ensure reliable communication with the support expert, because a Wi-Fi connection is usually only available in certain areas of the oil rig. In addition, fully automated enrollment of the system can be achieved with the Smart-Ex 02.

"In the medium term, the augmented reality capabilities of the Visor-Ex 01 can also make it significantly easier to train and support new specialists in remote plants," says Hartleb. For example, the corresponding information, digital work instructions, or efficient routes through the plant could be displayed on the OLED display of the Visor-Ex 01 when moving around the most important areas. Using the integrated loudspeaker or a Bluetooth headset with noise cancellation, which is also available from Pepperl+Fuchs, an expert can instruct the mobile worker remotely on what to observe in certain areas.

"The Visor-Ex 01 impressed the customer in the field testing phase with its versatile application options and excellent usability. The companies especially appreciated the intuitive operation of the smart glasses," concludes Henderson. The Visor-Ex 01 has initially been launched for applications in hazardous areas up to Zone 1/21 and Division 1. The approvals for Zone 2/22 and Division 2 will follow in the next quarter. With its worldwide certifications for hazardous areas, the Visor-Ex 01 is ready for the wide range of IIoT applications in process plants that do not want to forgo digital processes and remote support in the future.